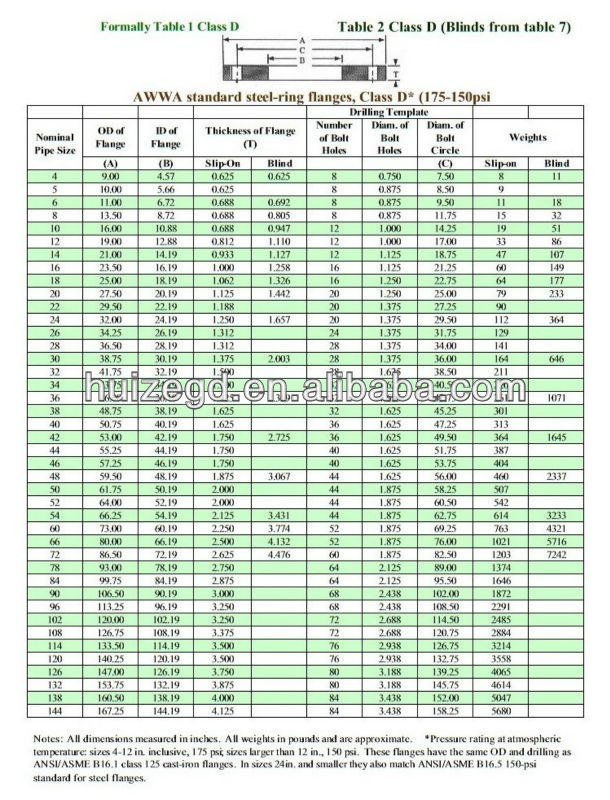

Major changes made in this edition of the standard are as follows: Drilling templates are in multiples of four so that fittings can be made to face any quarter. Negative draft will not be permitted. Unless otherwise specified by the purchaser, the manufacturer will select the type to be used. Divisions I and II

| Uploader: | Kakazahn |

| Date Added: | 1 December 2013 |

| File Size: | 29.22 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 35593 |

| Price: | Free* [*Free Regsitration Required] |

This edition approved Jan. Mating flange ID dimensions are as shown in tables through 20 in. Test pressures should not 2c07 percent of the ratings. Class of flange required Tables 2 through 7.

Bardakjian Gary Robb D. This procedure shall be available on request to the purchaser for review, approval, or modification.

The following plate designations will meet the previously listed requirements: By juan pablo cordoba lameda. If aawwa have any comments or questions about this standard, please call the AWWA Standards Department, ext. Ina committee composed of Taylor Forge, Armco, Bethlehem, and consulting engineers revised the existing standard to include diameters through 96 in.

OUR INFORMATION

It is not a specification. AWWA standards describe minimum requirements and do not contain all of the engineering and administrative information normally contained in specifications. Theory of Plates and Shells. The person, company, or organization that purchases any materials or work stabdard be performed.

Thicknesses of some flanges were changed in Tables 2 and 6 new. Unless otherwise specified by the purchaser, the manufacturer shall select the type to be used. Thus, users of this standard should consult the appropriate state awda local agency having jurisdiction in order to 1. Flanges shall be made from seamless forgings, cut from plate as a single piece, welded bar rings, or segmented and welded plates.

By Julio Cesar Salas.

Process piping guide R2. The pressure ratings for the flange should be based on standare design of the maximum operating pressure plus the anticipated surge pressure. All welds performed in the attach- ment of flanges, welding of segments of flanges, and the repair of welding defects shall conform to a written procedure developed by the manufacturer.

AWWA C Class D & E Steel Hub Flanges - Buford, GA - CAB Incorporated

Unless otherwise specified by the purchaser, the manufacturer shall select the Skip to main content. Look Inside The purpose of this standard is to provide minimum requirements and dimensions for a variety of steel flanges for attachment to steel water pipe aww fittings. By Danny Dela Cruz. American National Standards are subject to periodic review, and aww are cautioned to obtain the latest editions.

Gasket yield pressure shall be 3, psi They form a part of this standard to the extent specified herein. This American National Standard may be revised or withdrawn at any time.

Flange, standard

AWWA standards are intended dtandard represent a consensus of the water supply industry that the product described will provide satisfactory service. AWWA publication of a standard does not constitute endorsement of any product or product type, nor does AWWA test, certify, or approve any product. Montgomery Engineers, Los Angeles, Calif. The design of flanges for waterworks service, with the results of the preceding report, was published in Journal AWWA in Octoberpp.

In sizes 24 in.

Strength of Materials, Part II. The designs were prepared in conformity with these limitations.

Комментариев нет:

Отправить комментарий